Auto Lamp Assembly Line: Revolutionizing Automotive Lighting Production

In the modern automotive industry, efficiency, precision, and quality are the cornerstones of successful manufacturing. The production of automotive lighting—critical for vehicle safety and design—requires an advanced, highly efficient approach. This is where Auto Lamp Assembly Lines come into play, transforming the way lighting components such as headlights, tail lights, and signal lights are produced.

Automotive lighting is no longer just about functionality; it’s about durability, aesthetics, and precision. With technological advancements and automation, auto lamp assembly lines are revolutionizing the industry by streamlining production, improving quality control, and reducing production costs.

The Role of Auto Lamp Assembly Lines in Modern Manufacturing

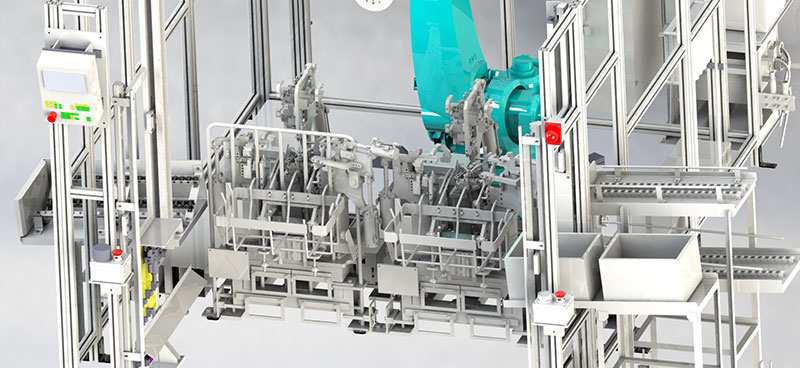

An auto lamp assembly line is a sophisticated, automated system designed to handle the entire production process of automotive lighting products. From assembling individual components such as bulbs, lenses, and reflectors to final testing and packaging, the assembly line ensures that every lighting product meets stringent quality standards.

Gone are the days of manual assembly that were time-consuming and prone to human error. Today’s assembly lines integrate robotics, artificial intelligence, and precision engineering to deliver consistent, high-quality products at scale.

Key Features of Modern Auto Lamp Assembly Lines

Automation and Robotics: One of the most significant innovations in auto lamp assembly lines is the use of automation. Robots and automated machines perform a variety of tasks, such as assembling lens and reflector units, inserting LED or halogen bulbs, and even applying coatings. The use of robots increases speed and accuracy, reduces the chance for defects, and ensures uniformity across large production runs.

Precision Assembly: Automotive lighting is a high-precision component, and small errors can lead to significant performance issues, including poor light distribution and glare. Automated assembly lines are equipped with advanced sensors and monitoring systems that guarantee precise assembly, ensuring that all parts fit together perfectly. From precise lens alignment to perfect bulb placement, every step is meticulously controlled.

Real-Time Quality Control: Modern assembly lines are designed to have built-in quality control checkpoints at every stage of production. Sensors, cameras, and AI-driven analytics continuously inspect each lighting component for defects or deviations from quality standards. This reduces the risk of defective products reaching the market and ensures that every lamp meets the required safety, performance, and aesthetic standards.

Speed and Scalability: With demand for automotive lighting components constantly increasing, manufacturers need production lines that can keep up with high-volume orders. Auto lamp assembly lines are designed for scalability, allowing manufacturers to increase or decrease production output based on demand. The integration of automated processes significantly speeds up production time, allowing for faster turnaround on large orders while maintaining high quality.

Customization and Flexibility: Modern auto lamp assembly lines offer greater flexibility when it comes to customization. Whether producing standard headlamps or more intricate designs for luxury cars, the assembly line can be adjusted to handle different models and specifications. This makes it easier to meet the unique needs of various vehicle manufacturers and customers, whether they require advanced lighting technologies like adaptive headlights or simple, conventional lighting solutions.

The Benefits of an Advanced Auto Lamp Assembly Line

Improved Efficiency: The key advantage of an auto lamp assembly line is its ability to produce large quantities of lighting components with minimal human intervention. The integration of automation ensures that processes are quicker, reducing downtime and increasing overall productivity. This leads to shorter lead times for clients, making manufacturers more competitive in the global market.

Enhanced Product Quality: With advanced technology and quality control mechanisms in place, the likelihood of producing defective lighting units is minimized. Each product is inspected and tested at various stages, ensuring that only those meeting strict standards are shipped out. The result is higher-quality, longer-lasting lighting systems that improve the safety and functionality of vehicles.

Cost-Effectiveness: While the initial investment in an automated assembly line can be significant, the long-term cost savings are undeniable. Automation reduces labor costs and the chance of human error, while speeding up production. This translates into lower overall production costs per unit, which benefits manufacturers and consumers alike.

Sustainability: As the automotive industry faces increasing pressure to reduce its environmental impact, auto lamp assembly lines are adapting by incorporating eco-friendly practices. For example, some assembly lines now utilize energy-efficient robots, recycle waste materials, and reduce emissions. Additionally, automated processes tend to be more precise, reducing waste and ensuring that fewer defective products end up in landfills.

Future Trends in Auto Lamp Assembly Lines

As technology continues to advance, the future of auto lamp assembly lines looks even more promising. Some emerging trends include:

Smart Automation: The integration of AI, machine learning, and data analytics is making assembly lines smarter. These systems can analyze production data in real-time, identify inefficiencies, and suggest improvements for optimization.

3D Printing: While still in the early stages, 3D printing technologies could revolutionize the production of custom lighting components, allowing for even greater flexibility and design possibilities.

Integration with Industry 4.0: With the rise of the Internet of Things (IoT), assembly lines are becoming more interconnected. Equipment can communicate with each other to optimize workflows, anticipate maintenance needs, and ensure uninterrupted production.

Conclusion

The Auto Lamp Assembly Line is more than just a manufacturing tool—it’s a game-changer for the automotive lighting industry. By embracing automation, precision engineering, and real-time quality control, these assembly lines are delivering products faster, at a higher quality, and at a lower cost. As technology continues to evolve, the capabilities of these assembly lines will only improve, further revolutionizing automotive lighting production.

For manufacturers looking to stay competitive in a rapidly changing market, investing in an advanced auto lamp assembly line is not just an option—it’s a necessity. Through cutting-edge technologies, these assembly lines are paving the way for the next generation of automotive lighting systems, delivering safer, more reliable, and aesthetically pleasing lighting solutions for vehicles worldwide.